Introduction

Filtration is the removal of fine solid matter from a liquid by passage

through a septum or layer having small openings. It is one of the major

industrial application that concern a wide rang of industries; basic chemicals

(like sulfuric acid or caustic soda manufacturing), water treatment, food

and beverage industry.

In various branches of industry filtering operations are carry out to

have liquids with maximum clarity, within a shorter time and less efforts

and costs. It's not possible to reach this ideal results of filtration

without a filter aid.

Filter aid

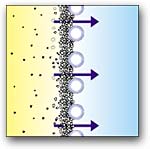

Without using a filter aid the solid particles in the liquid will soon

accumulate on filtering surfaces and block them. Here it comes the necessity

of using it.

Filter aid is an inert material which can make a filtering layer (cake)

that transfers the actual filtering from the septum to the whole mass

of filter aid. Filtration occurs in the tiny pores formed by the fine

particles of filter aid.

The difference between filtrations with and without filter aid

|

Filtration

|

|

|

WITH

FILTER AID

|

WITHOUT FILTER AID

|

|

- Fast filtration

|

- Filtration too slow

|

|

- Long Cycles

|

- Cycle too short

|

|

- Maximum clarity

|

- Clarity not good enough

|

|

- Very easy cleaning

|

- Filter very difficult to clean

|

PERLITE FILTER AID

Perlite is a unique filter aid made from volcanic rock which is expanded

and milled to a specific grades. The resulting filter aid is an extremely

pure, inert, white, lightweight material having a unique interlocking

structure with myriads of microscopic channels. It affords optimum flow

rates and sparkling clarity in filtered substances. Perltie does not impart

taste, odor or color to filtered liquids.

Therefore, it is excellent for filtering food, beverage and pharmaceutical

products.

MAJOR COST ADVANTAGE

Perlite filter aids provide the user with a density advantage of 20 -

50% over other filter aids which is an important consideration when comparing

costs. Perlite filter cake density is only 110 to 270kg/m3 . The dry density

of perlite filter aid ranges form 100 to 200 kg/m3. Experiences in a variety

of applications in many industries has shown that users of filter aids

can considerably reduce filtration costs without sacrificing performance

by converting to perlite filter aids.

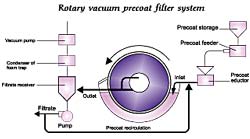

USABLE

WITH STANDARD EQUIPMENTS

USABLE

WITH STANDARD EQUIPMENTSPerlite filter aid can be used with both pressure and vacuum filtration equipment. When Perlite filter aids are used with rotary vacuum filters, filter cakes exhibit less cracking than when other filter aids are used.

HIGH FLOW RATE

Due to their unique physical structure, Perlite filter aids offer high

flow rates with optimum clarity. They are especially applicable to highly

viscous liquids such as syrup or gelatinous slurries requiring fast flow

rates.

Productivity, clarity , and flow rates may be increased through the use

of perlite filter aids.

EASY CAKE RELEASE

Because they remain porous and do not compact, perlite filter aids afford

easy cake release at the completion of a filtration cycle. Not only does

this facilitate filter cleaning, but it reduces manpower requirements

and increases productivity.

NON HAZARDOUS WASTE

Perlite is not hazardous waste and can be easily disposed of. Some cakes

used for food processing can even be recycled as components in animal

feed.

| PERLITE'S ADVANTAGES - Optimum clarity of filtered product - Variable flow rates - No color, taste, odor - Inert, Insoluble in acids. - Safe - less than .1% silica. - Non-hazardous. - Usable with standard filter equipment - Easy cake release - Facilitates filter cleaning - Less equipment abrasion - Easier to handle - Economical |

|

||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

| APPLICATIONS OF PERLTIE FILTER AID Food Processing: |

|

|

| - Cider - Corn Syrup - Fruit Juices - Sugar - Pectin - Citric Acid - Vegetable Oils - Vegetable Juices - Molasses - Soft Drinks - Casein |

|

|

|

Industrial:

- Water Treatmen - Oil Recovery - Pool Water Treatment - Greases - Solvent recovery |

Chemical - Inorganic Chemicals - Resins - Organic Chemicals - Sulfuric Acid - Polymers - Polyethylene - Adhesives - Titanium Dioxide - Fertilizers - Waste disposal |

|

|

Paints/Coatings/Textiles - Waxes - Oils - Varnish - Gums - Shellac - Paint |