Industrial applications for perlite are the most diverse,

ranging from high performance fillers for plastics to cements for petroleum,

water and geothermal wells. Other applications include its use as a filter

media for pharmaceuticals, food products, chemicals and water for municipal

systems and swimming pools.

Additional applications include its use as an abrasive in soaps, cleaners,

and polishes; and a variety of foundry applications utilizing perlite's

insulating properties and high heat resistance. This same heat resistant

property is taken advantage of when perlite is used in the manufacture

of refractory bricks, mortars, and pipe insulation.

Filter aid

The properties which give perlite filter aids a competitive advantage

over competitive products are their not toxicity and low bulk density.

Their low bulk density is very important for the cost effectiveness of

the process because at the filtration bed it is the volume of filteraids

that matters and not their mass. Perlite filteraids are also preferred

in many industries because they allow filtration equipment to filter liquids

at a faster rate and for a longer time without the filter septum to be

blocked.

Perlite filteraids are used in the filtration of wine, sugar and starch,

beverages, edible oil, as well as pharmaceuticals and chemicals.

Expanded perlite is an excellent filteraid, characterized by high purity

and inertness. It has the property of forming pre-coats and cakes of a

large number of pores, which can trap effectively the various solid impurities

from the liquid to be filtered. Their main advantages over competitive

products are their non-toxicity and low bulk density. Perlite filteraids

also facilitate the fast rate of filtration and high clarity of the liquid

E vacuated

and non evacuated Cryogenic service

vacuated

and non evacuated Cryogenic service

Perlite insulation suitable for evacuated and nonevacuated cryogenic service

exhibits low thermal conductivity throughout a range of temperatures,

pressures, and densitie s.

s.

In addition to excellent thermal properties, perlite insulation is relatively

low in cost, easy to handle and install, and does not shrink, well, warp

or slump. It also is noncombustible and meets fire regulations and can

reduce insurance costs.

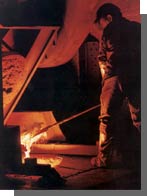

Perlite in the steel and Foundry Industries

Perlite insulation is used in high temperature applications in the steel

and foundry industries such as ladle topping, hot topping and risering,

in topping compounds, in exothermic and insulating shapes, as a cushioning

agent, in molding sand and in the manufacture of refractory blocks and

bricks.

Filler

Advantages of Perlite Hollow spheres or Bubbles as fillers

Because of their unique multicellular structure, these lightweight perlite

fillers can provide many advantages.

- They are effective bulk fillers because of their low density.

- Exhibit a uniform white color that has minimal to no effect on the color of the finished product.

- The particle shape of lightweight perlite fillers promotes good bonding between the perlite and resins.

- Some properties such as impact resistance and tensile strength may be enhanced by the particle shape and size of lightweight perlite fillers.

- Lightweight perlite fillers can reduce raw material costs while improving workability.

- when used with other fire retardant materials, lightweight , inert and inorganic perlite fillers can enhance fire resistance.

Because of these characteristics, perlite lightweight hollow spheres or bubbles have been found to be cost effective in a number of applications including the manufacture of adhesives, auto body putty, cultured marble, coatings, patching compounds and stucco.