![]()

Because of perlite's outstanding insulation, light

weight, fire retardant and sound control characteristics and its being

rot, vermin and termite resistant perlite is widely used in the following

construction applications.

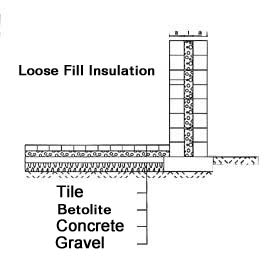

- Loose fill insulation

- Portland cement and gypsum plasters

- Underfloor insulation

- Concrete roof decks

- Chimney Linings

- Fireproofing

- Blocks

- Pipe insulation

Because of Perlite's outstanding insulating characteristics

and light weight, it is widely used a s

a loose-fill insulation. In this application, free flowing perlite loose-fill

masonry insulation is poured into the cavities of concrete block where

it completely fills all cores, crevices, mortar areas and ear holes

s

a loose-fill insulation. In this application, free flowing perlite loose-fill

masonry insulation is poured into the cavities of concrete block where

it completely fills all cores, crevices, mortar areas and ear holes

What is the benefits of perlite loose fill insulation?

- It is non combustible with a fusion point of approximately

1260oC. (2300oF).

- It is inorganic and is rot, vermin and termite resistant.

- It improves the fire rating.

- It is non settling and supports its own weight in masonry wall cavities and masonry block cores.

- It may be easily installed without special training or equipment.

Perlite can also be used as an aggregate in Portland

cement and gypsum plasters for exterior applications and for the fire

protection of beams and columns.

Traditionally plaster had been made from a mix of gypsum plaster and sand.

The problem with sand plaster is that in a fire the sand explodes and

cracks, and can be easily destroyed.

In contrast, perlite plaster can offer a product which is both lightweight

and fire-proof

- lightweight: it weighs approximately 60% less than ordinary sand plaster.

- Thermal Insulation: 4 times more resistant to heat transmission than sanded plaster thus permitting savings in air conditioning .

- Fire rating: Non- combustible and non- toxic provides up to 5 hours fire protection with minimum weight and thickness.

- Noise Reduction - Because of its porous structure

it doesn't permit sound reflection, it is sound absorbent and reduces

sound transmission between partitions.

Mixing of plaster Perlite:

For every two bags (100ltr per bag) of Perlite-C one sack of cement (50kg)

and 20-40lts lime plus water

Why Perlite Insulation?

Perlite underfloor insulation is an inorganic product that doesn't rot,

doesn't support combustion nor provide a habitat for rodents. Because

of its neutral PH, the product doesn't foster corrosion in piping and

electrical wiring that may be in the underfloor area and it is greatly

reduce sound transmission form floor to floor, form floors to walls and

from underfloor piping system.

When used for underfloor insulation, a water repellent, dust suppressed

perlite specially produced for this application is used.

It can be used:

under floating concrete floors,

asphalt floors

floating board floors.

Perlite concrete aggregate combined with portland cement

and water produces a lightweight insulating concrete used for lightweight

roof decks, floor fills, lightweight structural decks and many other applications

Benefits of concrete roofdeck insulating

- not combustible.

- superior fire ratings .

- lightweight and durable .

- reduce sound transmission .

- Excellent insulating value

- Slope to Drain

| PHISICAL PROPERTIES OF PERLITE CONCRETE | |||||

|

Perlite m3 |

Portland Cement kg | Water kg | Compressive strength(after28days)Kg/cm3 | Thermal conductivityw/m.C | Dry densityKg/m3 |

| 1 | 200 | 200 | 8 - 10 | 0.09 | 340 |

| 1 | 250 | 230 | 12 - 15 | 0.10 | 380 |

| 1 | 300 | 250 | 17 - 20 | 0.11 | 440 |

| 1 | 350 | 275 | 22 - 25 | 0.12 | 500 |

| 1 | 450 | 300 | 25 - 30 | 0.13 | 540 |

C ondensate,

which can form in chimneys when hot gases impinge on cold chimney linings,

can create two serious problems. The first is he formation of combustible

tars on chimney linings that may cause chimney fires. The second is the

formation of sulphite solutions that can attack chimney morter which can

lead to leakage, staining and possibly even chimney collapse.

ondensate,

which can form in chimneys when hot gases impinge on cold chimney linings,

can create two serious problems. The first is he formation of combustible

tars on chimney linings that may cause chimney fires. The second is the

formation of sulphite solutions that can attack chimney morter which can

lead to leakage, staining and possibly even chimney collapse.

Other reasons for relining chimneys are to deal broken or cracked masonry

work and to improve draft by reducing flue size.

Why Perlite?

- Perlite is inorganic.

- Doesn't support combustion.

- Exhibits excellent thermal insulting properties over wide range of temperature.

- Doesn't affected by most acids.

P erlite

blocks consist of Portland cement and expanded Perlite and it is same

in shape and dimension as ordinary blocks.

erlite

blocks consist of Portland cement and expanded Perlite and it is same

in shape and dimension as ordinary blocks.

Advantages of Perltie Blocks:

- Weighing much less than the half of traditional concrete blocks.

- Perlite concrete blocks provide excellent noise absorption.

- perlite concrete is non-toxic, rot, vermin and termite resistant and non-combustible.

- It is as permanent as the structure, which contains it.

- transportation, handling and installation is easier and faster.

|

|

|

||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

Lightweight perlite insulating concrete can play a multiple

role in undergroundpipe and duct installations . Perlite concrete insulation

can also serve as a supporting envelope . This latter advantage is of

special importance when pipe or ducts are laid under roadways , parking

lots or other areas subject to traffic. Perlite concrete pipe insulation

provides a monolithic

( seamless ) insulation for the length of a pipe or duct. Additionally

, Perlite insulating concrete is permanent, fire proof , rot proof and

vermin proof .